|

Nitrous Oxide How to make really big power! Power is produced by burning fuel. Add more fuel and enough air to burn that fuel, and the engine will produce more power. While the diesel engine fuel/air ratio isn't as critical as it is when tuning a gasoline engine, the ratio still needs to be kept reasonable to prevent overfueling and locomotive levels of black smoke. Earth's atmosphere contains approximately 21% oxygen - a critical element in internal combustion. Adding more oxygen to the combustion process allows for more fuel, thus increasing the thermal energy available to the engine. Turbochargers have long been used to add oxygen, by increasing manifold pressure. Up to a point, turbochargers are efficient and help to provide the necessary power increase that diesel owners are looking for. However, once past a certain level of boost pressure, the efficiency of the turbo and intercooler is overcome by increasing levels of heat accompanying higher boost pressures. An overfueled diesel engine will produce an unacceptable level of black smoke. One popular solution is to add nitrous oxide gas to the intake air. Properly set up, nitrous can add somewhere between 50 and 150 additional horsepower along with a big reduction in black smoke. Nitrous oxide provides two important benefits when injected into the intake system of a diesel engine. 1- Added oxygen: Nitrous oxide gas contains approximately 37% oxygen, greatly increasing the amount of oxygen available to the combustion process. 2- Cooler intake air temperatures: The transition from a high pressure liquid nitrous bottle through a small nozzle to a much lower intake manifold pressure greatly reduces the intake air temperature. Cooler intake air increases air density, which allows for more oxygen molecules to be packed into the same volume. Before moving on, I should point out that nitrous oxide injection is useful primarily for competition - situations that require short bursts of power, such as running for 10-15 seconds on a dyno, truck sled pull events or at the 1/4-mile track. Here, nitrous can help provide a huge % power gain. Nitrous is not very useful for RV'ers or heavy haulers. The lead-in photo shows our Duramax Diesel Project truck spinning the rollers at a spring 2005 dyno day. We ran the truck with a power module advertised at delivering fuel equal to an additional 170-horsepower, which allowed the truck to produce 420 rear wheel horsepower that day. Using just a size 51 nitrous jet, switching on the bottle produced an increase of an additional 50-horsepower for a total of 470. More fuel & nitrous will produce an even larger net gain. This "arms race" for more power can continue - at least till you discover the structural limits of the engine. With stock Duramax pistons and rods, this could be about 800-hp.

The folks at USDieselParts set us up with a Nitrous Express kit that was originally intended for a gasoline application (wet kit), but was tweaked for a diesel engine. Making the transition for use with a diesel engine is relatively easy, and far less complicated. This photo shows what all was included in the kit. As you'll see farther on, I wound up using only about half of the components to produce a single stage nitrous system. The wet kit (designed for simultaneous gasoline & nitrous injection) included many components that were originally intended for a gas engine. Two manifold pressure switches (3 psi & 20 psi), a fuel solenoid and the related components weren't used in this installation.

The 15-pound bottle is secured by two straps and mounts that are bolted to the bed. The outlet of the bottle is straight down through a pressure gauge and then a hole in the bed (protected by a rubber grommet). From there, a high-pressure stainless-steel braided line is secured inside the frame rail till sweeping up to make the connection to the nitrous solenoid valve inside the engine compartment. All of the pipe thread fittings must be installed using Teflon paste. The flare fittings are installed dry, without any Teflon.

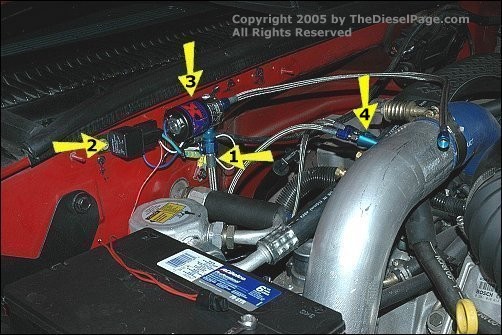

The high-pressure line (#1) sweeps up from the frame rail to connect to the nitrous solenoid valve (#3). The nitrous solenoid is switch-controlled by an electrical solenoid (#2). The braided stainless-steel output of the nitrous solenoid valve is then routed to the intercooler pipe (#4), where the nitrous is injected into the engine.

This photo shows the final setup. The plastic electrical cover encloses the nitrous solenoid valve and electrical solenoid to produce a clean and neat appearance. A set-screw was screwed into the fuel port of the nitrous nozzle to block it off. I could have configured the system to produce a 2-stage nitrous injection system, but felt any possible benefit was negated by the added complexity.

The nitrous arming switch was conveniently located in the removeable center panel of the dash. When staging at the track or preparing for a dyno run, this switch is toggled ON, but the nitrous won't flow till the "trigger" switch is also depressed.

The throttle activated "trigger" switch was supposed to be mounted to either the accelerator pedal assembly or to an underhood throttle mechanism (if on a gas engine). Though a new steering wheel with a built-in button is planned for our Duramax project truck, for now, I simply press the lever when nitrous is needed - usually once the Allison has shifted into 2nd gear and the torque converter has locked. The added 50-100 horsepower provided by nitrous is very noticeable when hitting the trigger!

Nitrous kits come with a selection of jets that can be used to fine tune the amount of injected nitrous. Experienced nitrous users recommend first installing a power module that overfuels the engine to some degree, producing excessive amounts of black smoke. Then, begin with a 40-50 size nitrous jet to see what effect it has on the black smoke. The level of black smoke should decrease as you add more nitrous through larger and larger jets - incrementing upward in units of ten (i.e. 50, 60, 70, etc.). Racers I've spoken to use 50 to 120 size jets, depending on how much power they're making. Making big power these days requires help to burn all of the fuel provided by the power modules and programs used in competition, and nitrous helps burn that fuel and make more power. Adding more nitrous than necessary doesn't appear to harm anything, but can actually decrease performance by over-cooling the combustion temperatures. There appears to be quite a wide latitude in the amount of spray that works for people, but performance testing is the best way to know for sure. See you at the track! Contact USDieselParts for any additional information about the available nitrous kits. TDP Did you find this article informative, helpful or entertaining? Send us an email to let us know. Nitrous Source: US Diesel Parts2400 Palmer - Missoula, Montana 59808 Call: 1-800-823-4444 -- Fax: 1-406-721-5097 www.usdieselparts.com What's New: | Feature Articles: | Product Reviews: | Member's Area: Join Us: | Duramax Diesel Page: | Advertisers: | Classified Ads: | Books:

Send e-mail to: turbo@TheDieselPage.com |