|

Fuel Filter Kit for the Duramax 6600 By Mittie M. Dragosljvich BACKGROUND In 2001, General Motors introduced the 6.6L Duramax turbocharged diesel engine in the 2500HD/3500 pickup trucks and chassis cabs along with a new Bosch high-pressure common-rail fuel injection system. Fuel pressures as high as 23,000-psi demand much from the high-pressure pump and solenoid-controlled fuel injectors, and the less than stellar quality and cleanliness of the available diesel fuel here in the US may present some durability and longevity challenges for these components. Supplemental fuel filtration may be required. Some Duramax owners have questioned the effectiveness of the OEM (Original Equipment Manufacturer) factory fuel filter; with concerns of costly premature fuel injector and fuel pump failure after the 5-year/100,000 mile factory warranty expires. Extensive research by Caterpillar and other manufacturers examining the effects of particle contamination and hydraulic component longevity has demonstrated a clear improvement in component life when reducing the level of particle contamination. Modern fuel injection systems are often compared to hydraulic systems since the operating concepts are similar. Discussions involving the need for additional fuel filtration have generated considerable interest among diesel enthusiasts. Recent topics found on TheDieselPage.com Bulletin Board Forum include debate on aftermarket fuel filtering options currently available from Baldwin, Caterpillar, Kennedy Diesel, Racor, and Stanadyne. After experiencing an on-vehicle failure of my own OEM Racor fuel filter, I became interested in adding supplemental fuel filtration to my 2001 Chevrolet 3500 Duramax diesel equipped truck.

This photo shows an OEM Racor fuel filter failure after 3,022 miles/124.7 hours. While servicing the fuel filter, a clanking noise from within the filter element provided a clue to the problems inside. The filter was inspected using an Airwolf AFC-570 filter cutter. Some may argue that the filter media was damaged during the inspection process, however the metal end cap separation was apparent while removing the fuel filter and before the cutting process began. In any event, separation of the end cap from the media canister would allow unfiltered fuel to bypass the filter media and flush accumulated debris from the dirty side of the filter directly into the fuel pump and fuel injectors. Although end cap separation is likely an infrequent occurrence, this event could provide a logical explanation for multiple simultaneous fuel injector failures.

Kennedy Diesel began working on a supplemental fuel filtering solution for the Duramax diesel during the later part of 2002. Their research led to a custom designed filter mount using a Baldwin BF7635 filter element. Advertised benefits for choosing a Baldwin BF7635 element include:

The MEGA filter mount is machined from a solid aluminum billet, and then anodized to eliminate rough edges and surface irregularities. The stainless steel 'O' ringed filter nipple is electro-polished to ensure a positive sealing surface for the filter element's integral post seal. This solidly constructed filter mount weighs approximately 1400 grams (almost 3 lbs.) without the stainless steel filter nipple. A dirty side bleeder port is accessible from the top of the filter mount. Kennedy Diesel's fuel filter kit is complete and appears well-engineered, containing the necessary fuel hose, fuel line fittings, and constant torque hose clamps. Thorough step-by-step instructions explain the MEGA installation as either a primary (pre OEM) or secondary (post OEM) fuel filter to supplement the OEM factory Racor fuel filter.

Kennedy Diesel's MEGA fuel filter kit. Fuel hose is included but not pictured. The white accent was added to outline the laser engraving on the filter mount, and is not present on production units.

Photo on the left shows the 2-micron rated Baldwin BF7635 used in the MEGA fuel filter kit compared to the factory installed Racor fuel filter. The Baldwin element includes an integral water separator/drain, and the filter media is specially treated to repel water.  The 2-micron rated Baldwin BF7635 filter (above left) used in the MEGA fuel filter kit versus the factory installed Racor fuel filter (above right).

Cut-away view demonstrating the BF7635's integral post seal and the electro-polished stainless steel filter nipple. This arrangement ensures a positive sealing surface to minimize filter and fuel contamination when replacing the filter. INSTALLATION The MEGA filter assembly installs under the factory air filter housing mounting tray, using stainless steel fasteners. Installing the Mega kit in another location may require fabrication of a custom bracket. Detailed instructions are included for installing the MEGA BF7635 as a primary (pre OEM) or secondary (post OEM) fuel filter. Installing the MEGA filter mount under the air filter assembly allows for its use as either a primary or a secondary, depending on how you route the fuel lines. Numerous opinions exist on choosing pre OEM versus post OEM supplemental fuel filter installation location. A pre-OEM location may cause less warranty issues depending on your GM dealer. A pre-OEM location should extend the service interval on the OEM Racor fuel filter, likewise shortening the service interval on the BF7635. In any event, GM's recommended service interval of 15,000 miles should not be exceeded for the OEM fuel filter. On the other hand, placing a coarser filter (larger micron rating) before a finer filter (smaller micron rating) is a generally accepted filtering principle. Since the BF7635's 2-micron rating appears to be better (a smaller micron rating) compared to the OEM Racor, a post OEM MEGA install follows accepted filtering principles. Servicing the OEM Racor at GM's recommended intervals will extend the service interval on the BF7635.

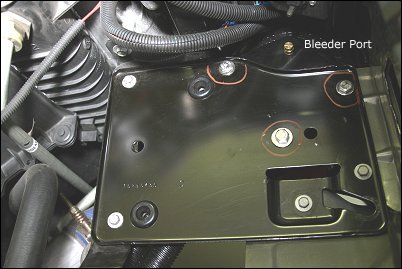

2001 Duramax factory air filter assembly and intake plumbing have been removed for this photo. The top of the photo is the front of the engine compartment. The three RED circles indicate the location of the bolts to mount the MEGA filter. The brass "dirty side" bleeder port is visible in the upper right, just above the leading edge of the OEM air filter assembly mounting plate.

This photo shows the MEGA filter hose routing, plumbed as a secondary filter (post OEM install) on a 2001 Duramax. Fuel line routing may vary on later model Duramax diesels and EGR/California emission equipped trucks. The LIGHT BLUE cable tie identifies the fuel line routing out of the OEM Racor filter mount to the 'IN' port on the MEGA filter mount. The YELLOW cable tie identifies the 'OUT' fuel line from the MEGA filter mount going to the Duramax fuel pump inlet.

MEGA filter hose routing as a secondary filter (post OEM install). The LIGHT BLUE cable ties identify the fuel line 'OUT' of the OEM filter mount to the 'IN' port on the MEGA filter mount. The YELLOW cable ties locate the fuel line routing from the MEGA 'OUT' port to the Duramax fuel pump 'IN'. Split loom tubing (3/4") can be used to protect the fuel lines from abrasion and give the installation an OEM appearance.

Here is a shot of the installed MEGA Baldwin BF7635 2-micron fuel filter as seen from the passenger's side with the inner fender liner removed. Note the horn location, repositioned to the upper left of the fuel filter mount and element. The passenger side horn must be repositioned to allow proper clearance for the large Baldwin element. Adding a washer or two between the rear most MEGA filter mounting bolt and the air filter assembly mounting plate angles the Baldwin element slightly forward, eliminating or minimizing contact between the filter element and the inner fender liner.

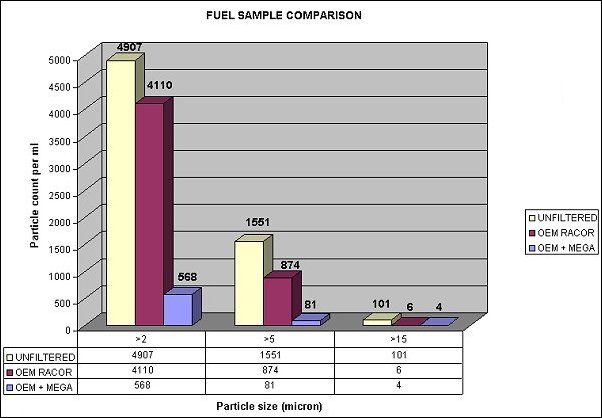

RESULTS Fuel testing was performed to compare the performance of the OEM Racor fuel filter to the OEM Racor primary + MEGA secondary fuel filter arrangement. On-vehicle fuel samples were obtained for unfiltered, OEM Racor filtered, OEM Racor + MEGA secondary filtered fuel, and sent to AV Lubricants Inc. for fuel analysis. A new OEM Racor fuel filter was installed at the same time as the Baldwin BF7635 to ensure a fair comparison. The filtered fuel samples were obtained from the Schrader test port at the front of the engine using the correct adapter. The unfiltered sample was obtained by disconnecting the 'IN' line from the OEM Racor filter mount. All fuel sampling was performed after filling a near EMPTY fuel tank to the FULL level with diesel fuel, and driving a short distance to the sampling site. Sampling in this fashion represents a 'first pass' result. Diesel fuel that is not used by the fuel injectors is returned to the fuel tank and re-circulated. I theorize that better fuel test results could be obtained by sampling after running a FULL tank to 1/4 tank, because the fuel will have made multiple passes through the filter(s) due to the fuel return system.  FUEL TESTS RESULTS GRAPH Tests confirmed that the MEGA fuel filter kit installed as a secondary fuel filter substantially decreased the particle counts compared to the OEM factory Racor fuel filter. Calculations indicate that the overall filter efficiency for all particle sizes greater than 2 microns for the OEM Racor was 16.24%, and improved dramatically to 88.42% for the OEM + MEGA secondary. The ISO Cleanliness Code improved from 19/18/14 for the unfiltered fuel, 19/17/10 for the OEM Racor, to 16/14/9 for the OEM + MEGA secondary. In this example, the ISO Cleanliness Code for >2 micron particles decreased from 19 to 16, for a decrease of (3) ISO Cleanliness Codes. A decrease of (1) ISO Cleanliness Code represents a particle count reduction to one-half of the original count, and should equate to a doubling of hydraulic component(s) life as reported by Caterpillar and others. Fuel injector and fuel pump life could be extended by at least 2X or more in this installation! SERVICE INTERVALS Recent inspection of the Baldwin BF7635 fuel filter element after 15,000 miles of use installed on a 2002 2500HD Duramax diesel as a secondary fuel filter revealed that it visually appeared clean. Replacement intervals for the Baldwin BF7635 fuel filter element should be in the 20,000 to 25,000 mile range, depending on the quality of the diesel fuel in your area. General Motors recommends servicing the OEM fuel filter at 15,000-mile intervals. Based on my experience with the OEM Racor fuel filter, I'm planning to service the primary OEM Racor fuel filter at 7500-mile intervals.

This Baldwin BF7635 filter element was inspected after 15,000 miles of use. The filter media appears to be in good condition. Depending on the quality of available diesel fuel, it could have likely remained in service until accumulating a total of at least 25,000 miles. The integral post seal is seen in the left foreground. Note the heavy gauge coil spring, used to maintain the proper seal between the media canister/integral post seal/filter case. The coil spring should also prevent separation of the metal end cap from the filter media canister at the water drain region. The volume of the BF7635 filter case with the media removed is over 3.0L. A Tavia 8340 filter cutter was used to inspect the 5 3/8" diameter BF7635.

John Kennedy contacted me shortly after installation of the MEGA fuel filter kit, and alerted me to possible 'air' entrapment in the BF7635 filter element when installed as a secondary filter (post OEM). Accumulated air-vapor can cause driveability concerns, including hard starting and stalling. The air entrapment/driveability issue seems to be limited to post OEM installation of the BF7635. Kennedy states that no driveability issues have been reported with primary (pre OEM) installation of his kit. In the absence of fuel system suction-side leaks, the air-vapor accumulating in the Baldwin element is a result of pressure and temperature induced release of the air-vapor normally present in diesel fuel. Baldwin's Technical Service Bulletin TSB-94-6R addresses this issue in suction /vacuum side filter installations, and the release of diesel fuel air-vapor in this situation may be considered normal. Decreasing the filter media pore size will increase the resistance to vapor passage through the filter media. The air-vapor entrapment occurs on the dirty side of the filter media, and the amount of air-vapor accumulation varies based on multiple factors outlined by the Baldwin TSB-94-6R. Since the MEGA filter mount provides a dirty side bleeder port that is lacking on many competing products, the presence of air entrapment can be quickly verified if driveability issues develop after installation. Installing a fuel lift pump between the fuel tank and fuel filter(s) to pressurize the fuel supply will minimize air entrapment in the Baldwin filter element. Early reports on fuel lift pump installations indicate a lack of air-vapor accumulation and correction of any related driveability issues. The installation of a fuel lift pump may provide additional benefits that are beyond the scope of this review. Shortly after installation, I bled the MEGA filter using the dirty side bleeder port found on the MEGA filter mount, and air-vapor was present. I've accumulated approximately 3,500 miles without incident, and do not plan to check for entrapped air-vapor unless a problem occurs. According to the vendor, current MEGA fuel filter kit buyers are made aware of the possible air-vapor issues prior to purchase.

Kennedy Diesel has assembled a high quality fuel-filtering package for the GM Duramax diesel, which offers Duramax owners a complete bolt-on solution to address their fuel filtration concerns. Possible benefits of supplemental fuel filtration and ultra-clean diesel fuel include improved engine performance, extended fuel pump and injector life, and many have reported improved fuel economy. If cleaner fuel with extended fuel injector and fuel pump service life sounds appealing, additional fuel filtration might be in order. TDP

At time of publication, the complete Duramax MEGA fuel filter kit was listed at $230.00, and includes (2) Baldwin BF7635 filter elements. Additional BF7635 filter elements cost $40.00 each, and Kennedy offers purchaser's of the MEGA kit an $8.00 discount on replacement filter elements if the instructions on his web site are followed at the time of ordering. Kennedy advises to "Always carry a spare filter for both the OEM factory fuel filter, and the auxiliary fuel filter at all times!" Technical References:

Airwolf Filter Corp

Baldwin Filters

Baldwin Filters Technical Service Bulletin

Caterpillar Inc.

Parker Filtration, Racor Division

Stanadyne Corporation

Tavia Performance Specialty Tools and Performance Products What's New: | Feature Articles: | Product Reviews: | Member's Area: Join Us: | Duramax Diesel Page: | Advertisers: | Classified Ads: | Books:

Send e-mail to: turbo@TheDieselPage.com |