|

Lubrication Specialist, LLC Universal Auxiliary Fuel Filter For the Duramax 6600 By Jim Bigley Fuel Quality can determine whether your diesel fuel injection system provides typical service or whether you are plagued with frequent visits to the dealership. GM recently upgraded the factory fuel filter element in an effort to help protect the Bosch high-pressure common-rail fuel injection system used by the Duramax 6600. Trapping more and smaller particles in the fuel can improve both fuel quality and injection system longevity. Lubrication Specialist Greg Landuyt has developed an easy to install and cost effective auxiliary fuel filter kit that can add a significant safety margin to the diesel fuel you're using. In a recent discussion with the folks at the Robert Bosch Corporation, I learned that the Bosch high-pressure common-rail fuel injection system incorporated into the Duramax 6600 will deliver designed life when fuel filter(s) provide 97% efficiency at removing 3-5 micron particles. A variety of fuel filters currently perform at those levels - including the fuel filter elements discussed here. Injector ball-seat erosion is thought to be due to particle contamination, and we know that cleaner fuel can improve injection system longevity.

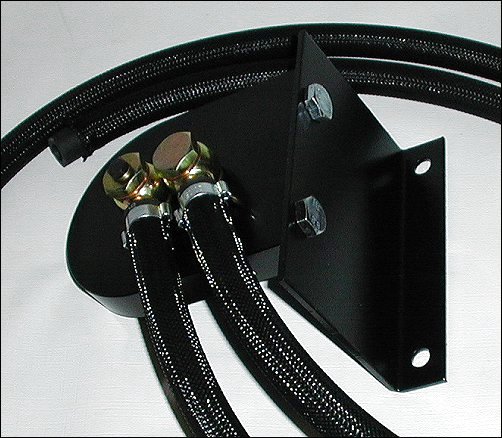

Perhaps one of the best features of the Lube Specialist fuel filter assembly is its ability to utilize a variety of 1"-14 thread diesel fuel filters, all with water separating capability. The list of potential filters include the Baldwin BF1223 3-Micron (shown), Wix 33411 3-Micron, Fleet Guard FS1287 3-Micron, Donaldson 3-Micron and the Racor R60S (T or P 2-30-Micron). If you choose the Racor filter, you'll need to buy the matching clear filter bowl, which can be ordered with or without a fuel heater and/or water in fuel sensor. Incidentally, Greg at Lube Specialist informed me that they stock both the Baldwin and Racor filters.

The included powder-coated bracket conveniently bolts onto the engine using two of the existing air conditioning compressor mounting bolts.

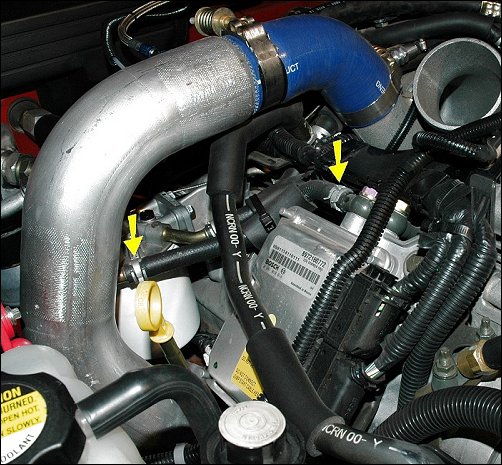

The filter mount takes clever advantage of the space set aside for a second alternator. The mount and filter element fit the space quite well, and provide better service access than just about any fuel filter we've seen - easy to replace and easy to check the water drain valve. The instructions included with the kit show an installation on a 2004.5 or newer LLY Duramax. The fuel line routing is different from the earlier LB7 Duramax shown here. Some interpretation may be required if yours differs from either these photos or those shown in the included installation instructions.

While the installation instructions show a "post-OEM" installation (fuel flows from the fuel tank to factory fuel filter, to the new auxiliary fuel filter, then to the engine), I chose a "pre-OEM" installation for a couple of reasons (fuel flows from the fuel tank to the new auxiliary fuel filter, to the original factory fuel filter, then to the engine). 1- Installing pre-OEM negates the potential for inadvertently introducing particle contamination on the "clean" side of the existing fuel supply. 2- The Lube Specialist auxiliary fuel filter is way more convenient to change and/or service than the original factory fuel filter. Whichever filter is first in line with the fuel tank will be changed approximately twice as often as the second filter. The arrows shown in this image are the connection points I used for a "pre-OEM" auxiliary fuel filter installation. The hose connection at the original fuel filter assembly should run to the center fitting (with air bleed) on the auxiliary fuel filter. Incidentally, if you choose to install your auxiliary fuel filter post-OEM, be sure the flush the output line of the new filter assembly before making the final hose connection. This'll help to reduce the possibility of contaminating the Bosch fuel injection pump.

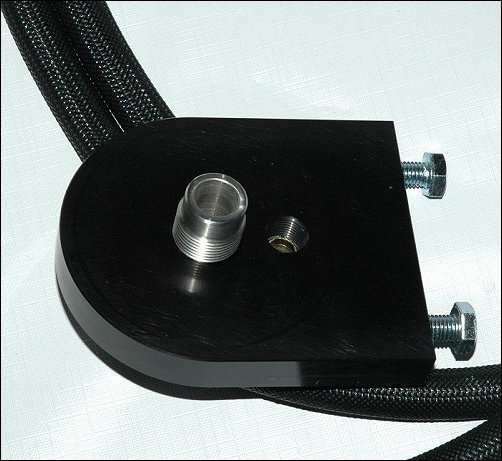

This image shows the included air bleed screw, which isn't necessary on a pre-OEM installation. I recommend filling a new filter with clean diesel fuel before screwing it onto the filter base mount, then use the air bleed screw on the original factory fuel filter base to remove any trapped air that may remain in the lines. With a 2-filter system, a safe regimen for filter service could include a 10,000 mile service interval for the first filter in-line with the fuel tank, and 20,000 mile service interval for the second fuel filter. Opinions vary on just how long you could or should run a fuel filter, but a fuel restriction gauge can be a big help in defining the exact timing of your fuel filter service. TDP Source:

Lubrication Specialist What's New: | Feature Articles: | Product Reviews: | Member's Area: Join Us: | Duramax Diesel Page: | Advertisers: | Classified Ads: | Books:

Send e-mail to: turbo@TheDieselPage.com |