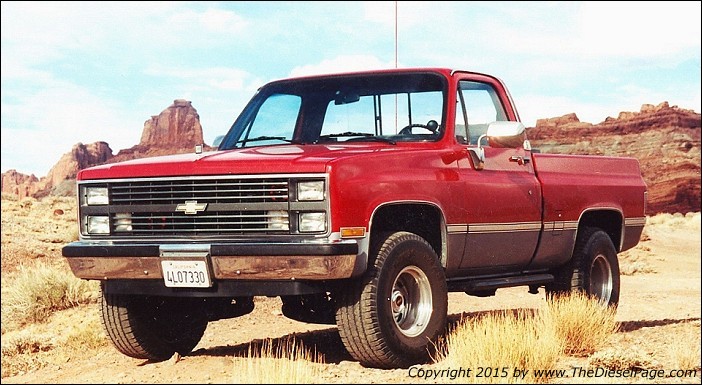

On location in Moab, Utah Dr. Lee's Perennial Project Truck By Lee Swanger, The Diesel Page Member # 006 My 1984 C-10 Short-bed has served as a test-bed and project truck for a number of improvements in performance, and appearance since 1991. The best investment I ever made was joining The Diesel Page in 1996. This article is a summary of some of the projects undertaken on this truck, originally equipped with the light-duty 6.2L diesel, 700R4 transmission, and economy-oriented 2.73 rear axle gears. I will be posting more information on The Diesel Page Forum in the near future. So, hoping to inspire the next generation to step up and take responsibility for keeping this 30-year-old senior citizen of the GM and Chevy diesel truck world on the road and representing the diesel heritage, I am reluctantly announcing that: My Truck Is For Sale! Some of the more interesting modifications to my truck have been published in detail on The Diesel Page, and included in the 6.2L books available here. The major areas of discussion will be: the engine; the 700R4 transmission; the rest of the drivetrain; suspension and running gear; and other modifications. Engine Modifications and Replacement: The heart of any pickup truck is the engine, and GM light truck diesel engines are the reason The Diesel Page exists. After discovering The Diesel Page, my interest in improving my engine ramped up considerably. I added the heavy duty "J" code intake manifold and bought a new (rebuilt) Stanadyne injector pump and injectors for a major tune-up. I also tore into the front end of the engine to add a camshaft gear drive to replace the timing chain and sprockets. My next goal was a major power upgrade to my engine, either with a turbocharger or with nitrous oxide and propane, but thanks to The Diesel Page, I now knew about the possibility of block cracks near the main bearing bores in the 6.2L. Sure enough, my block was a victim of the design and metallurgy of the 1983-1989 castings, so no power upgrades for this block. But . . . as readers of The Diesel Page know, in the spring of 2002, I acquired a remanufactured 6.5L engine and wrote a pair of articles that appeared on The Diesel Page later that year. The new engine for my truck has a firm foundation, the more desirable 599 engine block. I had decided to stay with a naturally aspirated (NA) engine (no turbocharger) so we specified the smaller 6.5L naturally aspirated pre-combustion chamber cups. The cylinder heads were pre-fitted with the coolant bore bushings between the intake and exhaust passages to eliminate any coolant leaks in the future. The engine was fitted with a gear-drive for the camshaft, and the engine was topped off with a fresh 4911 mechanical injection pump from the turbocharged 6.5L engine, a heavy-duty "J" intake manifold and NA exhaust manifolds, all carefully port-matched to the cylinder heads for maximum power and efficiency.

This could be your engine, because This Truck and Engine are For Sale! After installation and a few miles of break-in acceleration runs, I headed back to Miami, with a completely different truck. The seat-of-the-pants impression was that I had about twice the power, which could have been close to true since the original engine had 145,000 miles on it, and was low on compression. With the new engine, I could spin the rear tires on take-off. Now it was time to add some extra power, via nitrous oxide and propane. We can think of nitrous oxide as "chemical supercharging"; it provides extra oxygen into the engine. To use that oxygen, there has to be fuel to burn. I had turned up the DB2 4911 high pressure fuel injection pump to provide extra fuel when the go-pedal was pressed all the way to the floor. To make even better use of the nitrous oxide, extra fuel in the form of propane would be added only when it is needed. I installed the solenoid valves that control the nitrous oxide and propane, and the nozzle that squirts them into the intake, on the intake manifold. I also installed a micro-switch so that the nitrous and propane would only be activated a full throttle.  Nitrous and propane solenoid valves, and hoses leading to the injection nozzle An additional benefit of injecting liquid nitrous and propane into the intake is that evaporation of the liquids will cool the intake air significantly. Denser air will fill the cylinders, further aiding in burning added diesel fuel and propane. Now, 45,000 miles later, this engine is still running just as strong as after break-in. The purchaser of my truck will own a strong custom engine with another good 150,000 miles to go, if he continues to maintain it with regular oil changes with high-quality 15W-40 diesel lubricating oil. Remember, This Truck is For Sale! 700R4 Transmission Upgrades With a strong engine I now needed a durable transmission. I selected a specialist to build me a diesel-specific transmission, based on the heavy-duty "K" case intended for four-wheel-drive trucks. This transmission included better clutches and bands, a diesel governor, an upgraded front pump, better sprag clutches, a strengthened drum, and a custom shift kit to firm up the shifts. To assure a long and happy life for the transmission, I added an external transmission filter to supplement the filter in the transmission pan, an external transmission fluid cooler to supplement the cooler built into the radiator, and a deep transmission pan to increase the amount of transmission fluid in circulation.  Extra filters and transmission cooler, behind the front bumper The black filter is the external transmission filter, and the finned item is the transmission fluid cooler. The white filter is a bypass lube oil filter for the engine oil. This photo shows the location of these auxiliary components behind the front bumper and ahead of the anti-sway bar. The next owner of my truck will have an excellent transmission with only 5,000 miles of operation on it. After all, remember that This Truck is For Sale! Additional Drivetrain Upgrades The rear axle was also upgraded. I replaced the original 2.73 gears in the 10-bolt axle (put in as part of GM's fuel economy plan at the time) with 3.73 gears, and I replaced the original open differential with an Auburn conical clutch limited slip differential. Suspension, Brakes and Other Modifications I decided that a five-inch lift in the front would clear the popular 33x12.50R15 tires. I chose to go the suspension lift route. The back would be easy - leaf springs can be augmented with lifting blocks, add-a-leaf, or re-arched springs. Adding Rancho air shocks to the back would keep the truck level even with a load of bricks or sand in the bed. The front independent suspension was more of a challenge. I enrolled in a welding course at the local junior college to perfect my arc-welding skills before designing, fabricating, and installing my front five-inch lift. The next photo shows the adapter I made to relocate the lower A-arm of the suspension to lift the frame of the truck up five inches.  Step one in lifting the front suspension, dropping the lower A-arm There is a spacer above the coil spring so that the spring would support the truck in its new lifted configuration. The next challenge was to attach the upper A-arm of the suspension to the steering knuckle without totally changing the geometry. I used a CAD (computer-assisted-design) program on my PC to lay out the original and modified geometry of the front suspension, to minimize bump-steer and camber changes during suspension travel. The next picture shows the adapter I made, and also shows the extension I made for the tie rod connection to the steering knuckle.  Front suspension modifications: ball joint and tie rod extenders With the front and rear suspension lift in place, I added Weld Racing forged aluminum wheels (15 x 10) and 33x12.50R15 tires. The current tires only have about 2,500 miles on them, so the next owner of my truck will have good tires for quite a while before needing to think about replacements. Remember, This Truck is For Sale! It has been about ten years since I installed disc brakes on the rear axle of my truck as an upgrade over the original drum brakes. The article that I wrote about the conversion is still posted on TheDieselPage.com. Stainless Steel Brakes provides a very comprehensive kit for this upgrade, and it includes calipers originally designed for the Ford Thunderbird and V-8 Mustang, so replacement pads are readily available. When I completed this work, the newly installed disc brake assembly looked like this:  Rear disc brakes to replace OEM drums The result is smooth, linear braking, better front-to-rear balance, reduced un-sprung weight, less sensitivity to water on the road, and easier maintenance. The original rear disc brake pads that I installed have only 22,000 miles of service, and are still in good shape. I did purchase a set of replacement pads, which will go to the next owner, because This Truck Is For Sale! Knowledgeable diesel drivers have learned that the best indicator of how hard your engine is working as to monitor the exhaust gas temperature, and the engine RPM. My truck did not come with either of these essential instruments, so I added them.

Tachometer is located on top of dash, and exhaust gas temperature gauge in lower left location. The exhaust gas temperature gauge is mounted in an extra space at the bottom left of the dash, and connected to a thermocouple in the exhaust pipe just below the left exhaust manifold. The VDO tachometer is mounted on top of the dash, and is driven by the engine speed sensor. My article describing the custom circuit I designed and built to match the Tach to the engine speed sensor is still available at TheDieselPage.com. I have tweaked my trucks electrical accessories as well. One important update was to replace the electro-mechanical glow plug controller on the early diesel trucks with the integrated controller and relay from the later diesels. Since I had become somewhat fond of my truck, I added an alarm system with two sirens, and added power door locks, integrated with the alarm, the automatically lock the doors when the alarm is armed, and unlock them when disarming it. I know, this is something we take for granted in the second decade of the twenty-first century, but in 1984 that was a novel concept! Remember, all of this can be yours very soon, because This Truck is For Sale!  The truck's current home in Miami. It will look just as good sitting in the next owner's driveway As far as the external appearance of my truck is concerned, except for the big tires, the modifications have been pretty subtle. My truck is missing a rear bumper so that the truck will fit in my garage. The original step bumper was replaced with a fiberglass rear roll pan. I also wanted a trailer hitch, for those rare occasions when I needed to tow something, or more frequently, carry a pair of bicycles properly with a bike carrier. And finally, little touches like the DeeZee stainless steel side step bars, the locks on the fuel filler doors, the shaved (i.e. removed) emblems from the front fenders, and the minor trimming and reforming of the front wheel wells to fit the big tires during tight turns might be noticed, if you look closely. I have also put in a roll-up tonneau bed cover. For those of you familiar with the 1973 - 87 C-K trucks with the dual side saddle fuel tanks, you know there is a fuel filler on each side of the truck, and to fill the tanks you either reposition the truck between tank fillings, or drag the fuel pump hose across the bed to get to the other side. I solved this by putting a cross-connection between the two tanks so both can be completely filled from one side, as long as I put my custom vent tube in the opposite filler. The custom vent tube, with instructions will go to the next owner because This Truck is For Sale! You can contact me through my email address: clevitekid@yahoo.com, or through the web site contact information listed below to learn more. Written by Dr. Lee Swanger, the following stories appeared here in The Diesel Page some years ago that discussed upgrades that Dr. Lee performed on his truck. We're re-running them now to illustrate the value and performance for what Dr. Lee has done. Custom Rear Disc BrakesCustom 6.5L Diesel Engine Custom 4-Speed 700R4 Automatic Overdrive - Part I Custom 4-Speed 700R4 Automatic Overdrive - Part II What's New: | Feature Articles: | Product Reviews: | Member's Area: Join Us: | Duramax Diesel Page: | Advertisers: | Classified Ads: | Books:

Send e-mail to: turbo@TheDieselPage.com |